Before we get into the specifics of leak-by, let’s establish some basics about the bioprocessing environment where the Brooks Instrument SLA Series Biotech excels.

The Role of the Mass Flow Controller (MFC) in Bioprocessing

The typical bioreactor is a vessel where a batch process is used to grow micro-organisms (ex. yeast, bacteria, mammalian cells, etc). The vessel is seeded with a live cell culture and fed with a nutrient (ex. glucose, glycerol/methanol) plus trace minerals. The type of cells employed might be simple prokaryotes (bacteria) or the more complex eukaryotes (yeast, plant, mammalian, etc.). The latter can be extremely ‘finicky’ in their needs for a stable growth environment, but, they can perform biochemical feats that simpler cells cannot (e.g. ‘post-processes’ such as glycolation – attachment of sugar-chains to proteins). The final product might be proteins such as insulin, monoclonal-antibodies, growth-hormone, antibiotics or vaccines.

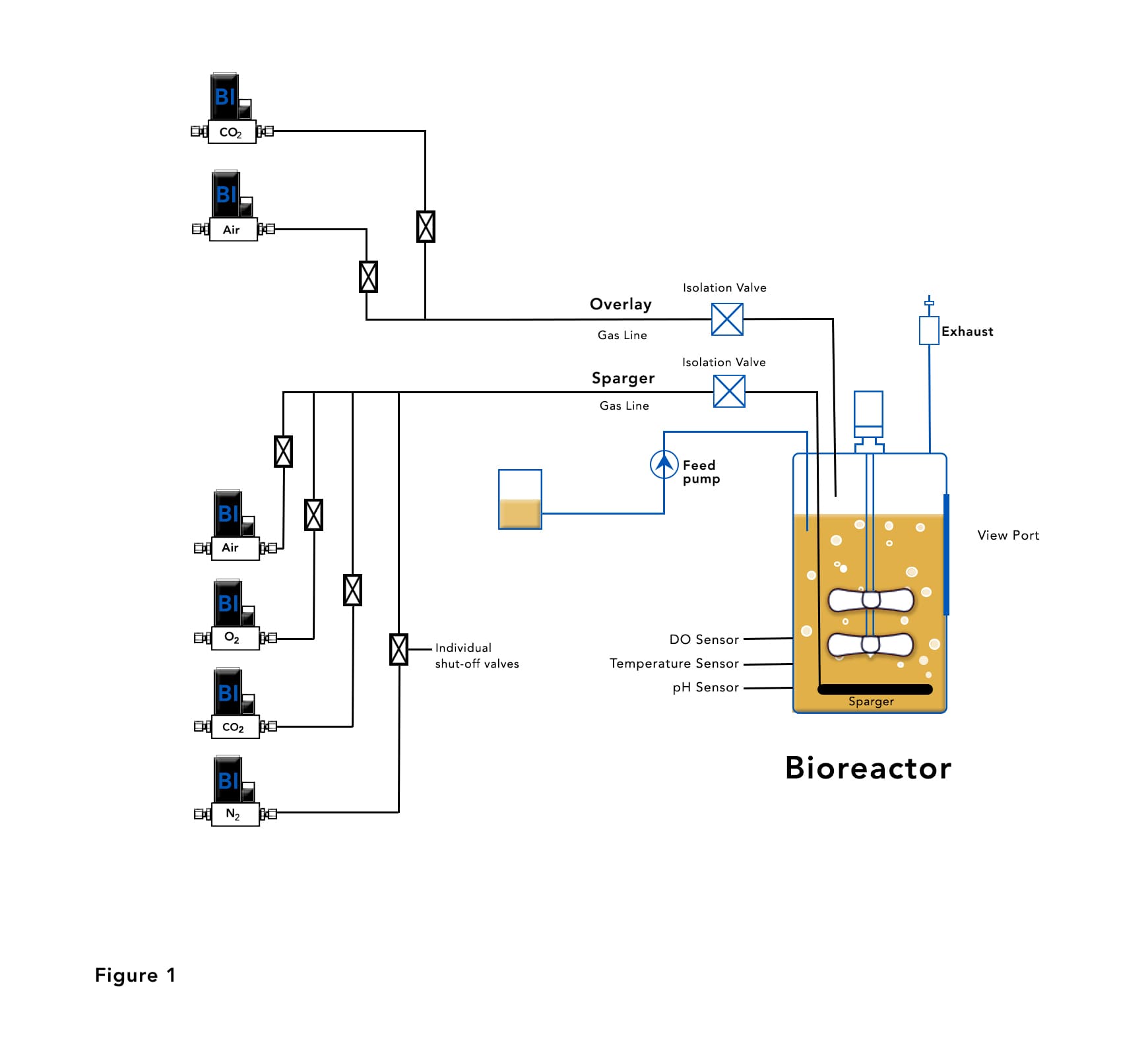

The bioreactor is set up with DO, pH and temperature sensors, a nutrient feed, gas controllers for overlay and sparge gas feeds and a mixer/agitator. Tight control of dissolved-oxygen levels (enriching Air flow with O2, or depleting it with N2) better regulates cell-growth-rate, reduces production of toxic cell by-products, and thus increases bioreactor yields. Tight control of pH (e.g. via CO2 flow, with N2 ‘makeup’) is important as well (e.g. to inhibit the activities of proteinases); Acids and bases injected in a liquid solution can be used for pH control, but can be ‘harsh’ on delicate mammalian cells.

Agitator (impeller) speed controls are important as well, in increasing gas absorption (but too much agitation can rupture delicate cells). A CO2 exhaust gas analyzer might be used to help understand total respiration (carbon cycle), and lead to better-controlled cell-growth-rate via nutrient feed rate controls.

Finally, we get to the good part! Where does Brooks Instrument come in? Mass flow controllers (MFCs) are often used to control the dissolved oxygen (DO) and potential hydrogen (pH) in a bioreactor, as shown in Figure 1. MFCs themselves combine a flow sensor, control valve and on-board control electronics in one small integrated package, capable of measuring and controlling the flow rate of a given fluid to the user’s specified flow rate. Curious how our MFCs work? Check out our Theory of Operation Video.

What Features of an MFC Matter in Bioprocessing?

Mass flow control valves have a challenging, multifaceted job: they must precisely regulate flow to a small fraction of a percent over a wide range of operating conditions using very low power. These operational requirements result in valves that operate with very low forces. This limits the amount of force available for shut-off.

In Figure 1 the valves are open, the mass flow controllers are receiving gas delivery setpoints from the control system and are delivering gas to both the sparger and the overlay/head gas space. You can see the gas bubble coming up from the sparger at the bottom of the vessel.

To meet its published turndown ratio, a mass flow control valve must be able to “shut off” below the minimum flow required to satisfy the turn down ratio. For example, a 10 slpm (10,000 sccm) instrument with a 100:1 turn down will need to shut down below 10 slpm/100 (10,000 sccm/100) or 100 sccm. Even if the control valve shuts down 4 times better than required it will still leak 25 sccm. While meeting specification, the leakage allows a significant amount of gas past the valve that is not expected, which may cause operational issues in the overall process.

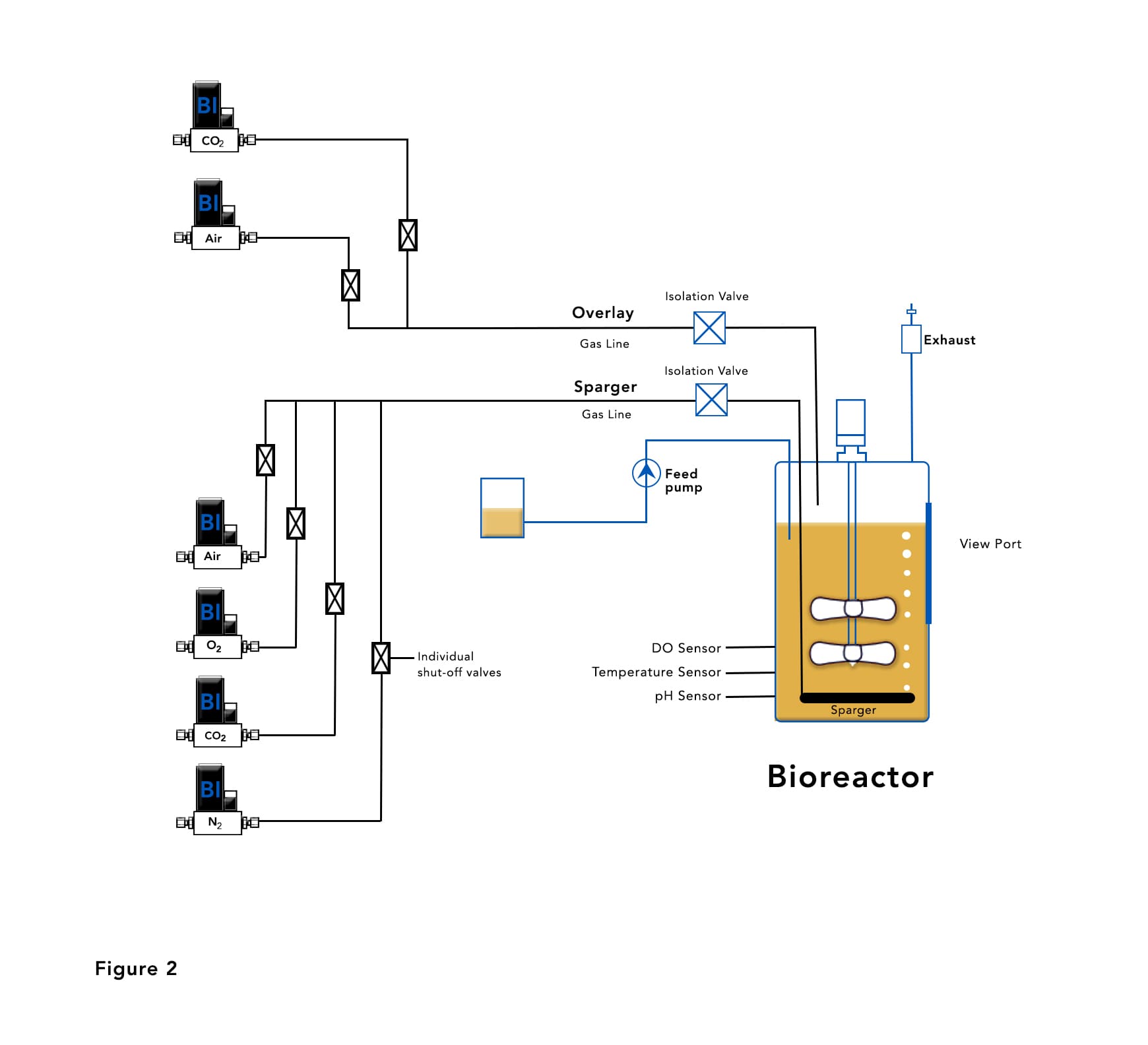

In Figure 2 the valves are open and the mass flow controllers are NOT receiving any gas delivery setpoints from the control system. You can see the small stream gas bubble coming up from the sparger at the bottom of the vessel. This is a small amount of gas leaking past the MFC control valves. In many cases this nuisance leakage is too small for the MFC to measure, but still large enough to be an issue.

More than just a Nuisance – How Can You Avoid Nuisance Leakage?

Before we jump to the solution, let’s review the many undesirable effects of a nuisance leakage:

- Gas usage even when the MFC is “off”. This may be a simple nuisance where the gas supply is drained overnight or when the process is turned off for extended time.

- Nuisance leakage. This may be a perceived quality issue in the case of a bioreactor where bubbles are seen in the viewport, even when the gas is “off” (Figure 2)

- Requirement of a shutoff valve for every MFC to ensure gas can be shut off.

- Possibility of allowing incompatible chemistries into the process.

- Unwanted pressurization of outlet tubing – In the case where the outlet of the MFC is connected to the process with low pressure disposable tubing, the outlet tubing can become pressurized to the MFC inlet pressure which may exceed the pressure capability of the disposable tubing.

- Unwanted pressurization of process chamber – In the case where the process chamber is a low pressure disposable type, it can become pressurized to the MFC inlet pressure which may exceed the pressure capability of the disposable process chamber.

- Unwanted changes in the process – If the is a small amount of fluid flowing continuously into the process when the flow is intended to be zero, the process results may be affected. In the case of a bioreactor, the DO or pH levels may be affected.

- Apparent drift in zero signal. Small leaks past the control valve may appear to be a change in the zero flow output from the MFC, which can look like the MFC flow signal is drifting, when the MFC is actually correctly reporting the flow that is leaking past the valve.

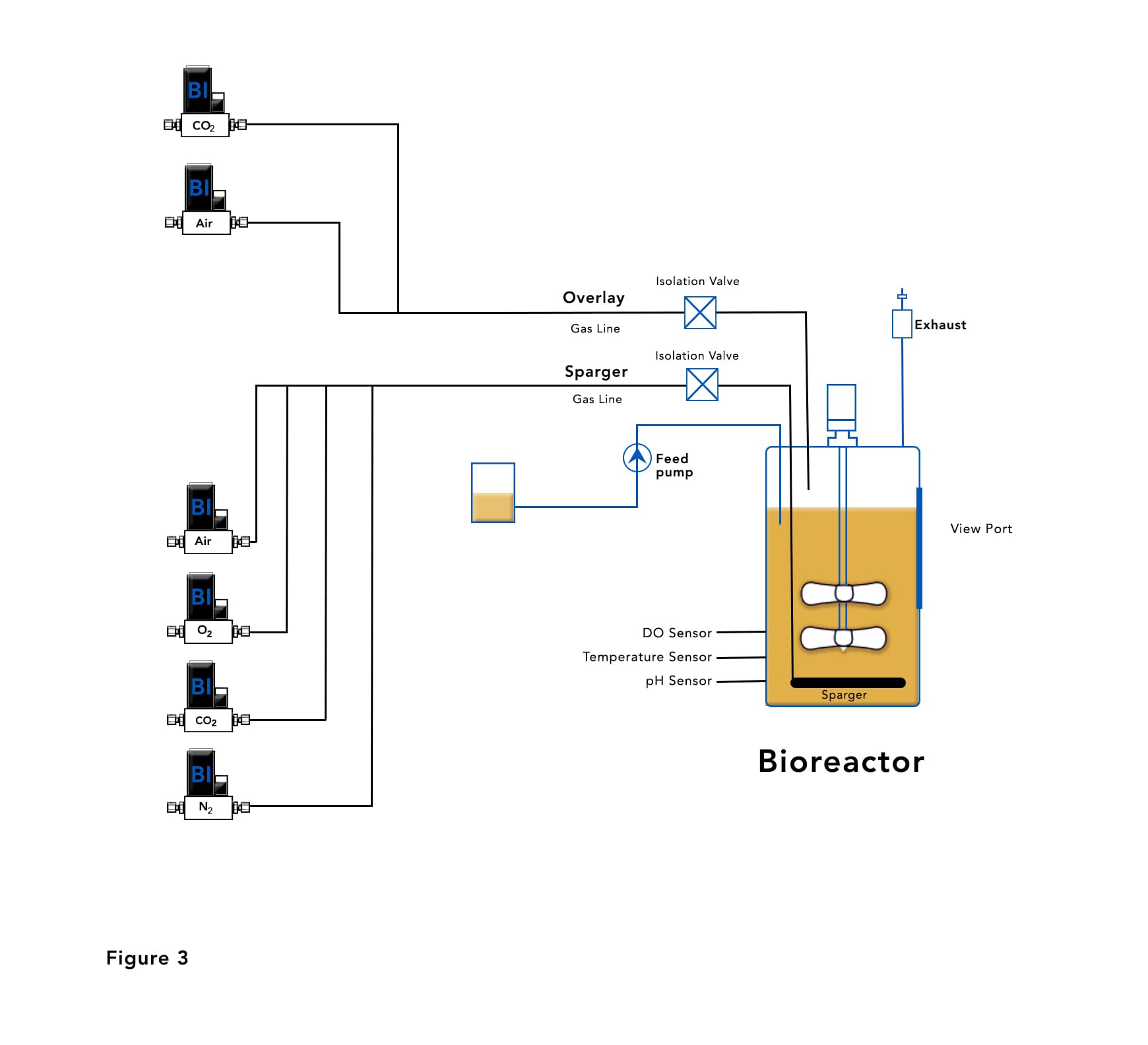

Brooks has addressed the issue of nuisance leakage by improving the valve assembly process to better control leakage past the control valve. The valves manufactured for Biotech application undergo an initial mechanical setting of the critical dimensions to 0.0001” (one ten thousandth of an inch) tolerance to assure “leak tight shut off” while still giving precise flow control. In addition, each valve is flow tested on a dedicated valve test stand to assure good performance over a wide operating range. These additional steps both improve the control performance of the MFC and eliminate nuisance leaks, potentially also eliminating the need for individual shut-off valves, as shown in Figure 3.

In Figure 3 the individual shut off valves are eliminated reducing the cost of the overall system. The mass flow controllers are NOT receiving any gas delivery setpoints from the control system and are acting as shut off valves in this instance. You see no gas bubble coming up from the sparger at the bottom of the vessel.

To learn more about Brooks’ superior turndown and leak-by see the model family SLA5800 (IP40 housing) or SLAMF (IP66 housing) with the Biotech options. These products boast up to 250:1 turndown and a leak past the control valve of less than 0.005 sccm among many other features especially valued in bio-processing applications. To determine which SLA Series Biotech makes sense for your process, try our Solution Finder.

Component datasource missing. Select a datasource for this component.