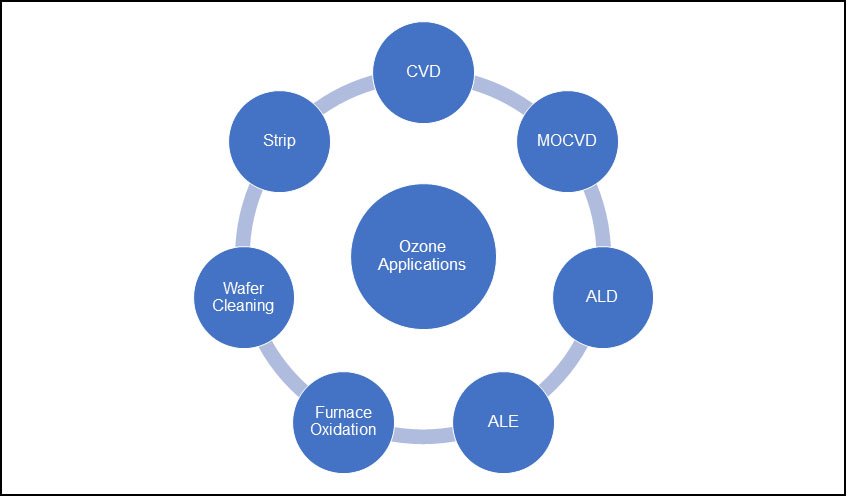

Ozone is a powerful oxidiser used in a wide variety of applications within semiconductor manufacturing. It can enable the production of many oxide compounds and complex structures with fast reaction rates, making it a practical choice for semiconductor manufacturing processes. Applications for ozone include: Chemical Vapour Deposition (CVD), Metal Organic Chemical Vapour Deposition (MOCVD), Atomic Layer Deposition (ALD), Atomic Layer Etch (ALE), Furnace Oxidation, Wafer Cleaning and Strip.

Some applications, such as ALD, may require ozone to be supplied at very low pressures (5 psia) to the process chamber. Meanwhile, ozone is an unstable compound that will rapidly decompose with higher temperatures. A Brooks Instrument GP200 Series pressure-based mass flow controller (P-MFC) can measure and control ozone at very low pressures without contributing to the thermal decomposition of the gas is ultimately required for these conditions.

Application Requirements

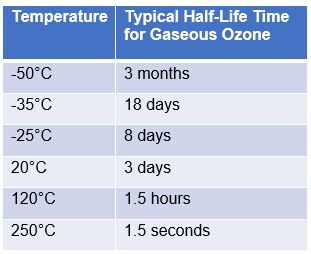

Ozone will decay into oxygen over time, with this effect being exacerbated by an increase in temperature. Table 1 below illustrates how ozone decay can be accelerated with heat. Ozone can also be destroyed catalytically by exposure to various oxides (MnO2, MgO2, Fe2O3), further accelerating decomposition.

Table 1

As ozone decomposes, energy is released in an exothermic reaction, resulting in heat. If it is not controlled properly, the decomposition of ozone can lead to superheating issues.

Ozone Decomposition:

O3 = O2 + [O]

[O] + O3 = 2 O2

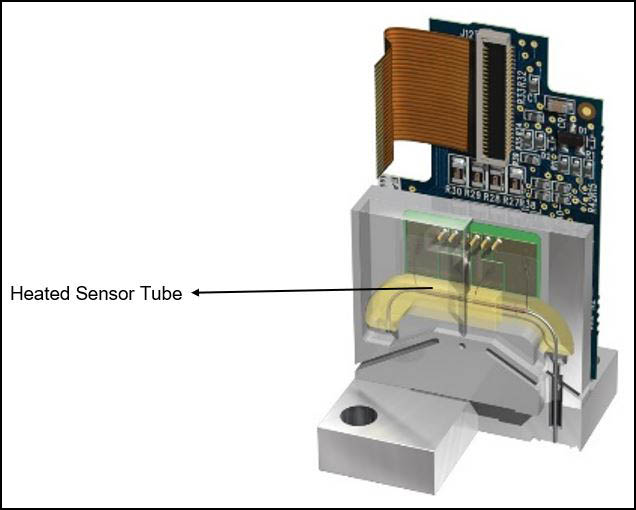

Typically, in the case of thermal mass flow meters, the gas passes through a heated sensor tube. The difference in temperature between the resistance temperature detectors is utilised to determine the flow rate through the sensor tube. In ozone applications, the additional heat that the ozone is exposed to in the heated sensor tube accelerates the decay. Because of this decomposition, the measured difference in the sensor tube will not be an accurate representation of the true gas flow through the thermal mass flow controller bypass. Over time, ozone’s continued decomposition will cause greater instability, accuracy, and control issues ultimately leading to a shorter lifetime in thermal mass flow controllers. The Brooks Instrument GF Series thermal mass flow controllers are optimised for gases prone to thermal decomposition and includes a thermal sensor that operates 20-30°C cooler versus competitive sensors.

Process Solution

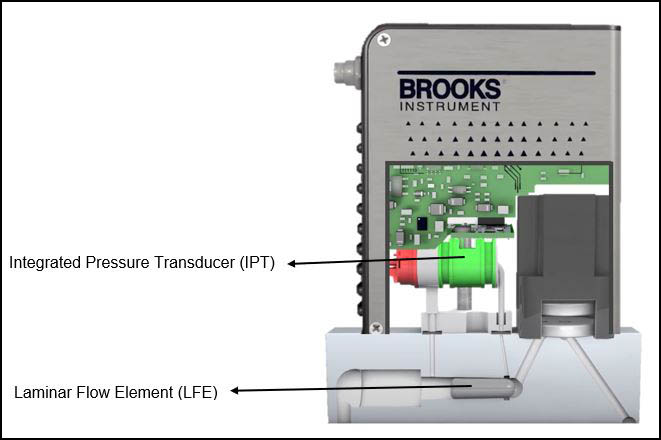

For an even longer lifetime, a GP200 Series pressure-based mass flow controller (P-MFC) is recommended. Featuring a unique and patented Integrated Pressure Transducer (IPT), this IPT enables the use of a low pressure drop laminar flow element (LFE) that is designed to operate at 1 psid, making the GP200 Series pressured-based mass flow controller (P-MFC) an optimal solution for both low-pressure and high-pressure gases. The IPT utilises a single diaphragm to measure the true differential pressure (∆P) and this precise ∆P measurement is used directly to calculate mass flow rate.

Watch this GP200 Series theory of operation video to learn more:

The GP200 Series pressure-based mass flow controller (P-MFC) is compatible with all gases and provides safer low-pressure operation that is typically required for ozone applications.

To ensure that the mass flow controller is not contributing to the decomposition of ozone, or other gases prone to thermal decomposition, no heated elements are used internal to the GP200 Series pressure-based mass flow controller (P-MFC). By not adding heat to the gas during flow control, ozone will not decompose thermally inside of the mass flow controller and will not cause any measurement uncertainty due to deterioration. When the GP200 Series pressure-based mass flow controller (P-MFC) is used to control ozone mixtures there will not be any decomposition or deterioration, resulting in a longer lifetime for the mass flow controller and more accurate ozone flow control.

Over time, a GP200 Series pressure-based mass flow controller (P-MFC) utilised for ozone mixtures will allow for greater stability, accuracy, control, and a longer lifetime for the mass flow controller.

For more information about the GP200 Series pressure-based mass flow controller, visit this resource page.