Last month, scientists from 60 countries convened in Versailles, France to change the definition of the kilogram (Kg). Instead of basing the kilogram on a physical piece of material - as has been the case for over a century - the kilogram is now based on a universal constant. While the new kilogram standard will impact industries involved in measuring very small or very large masses, it’s impact on flow measurement and instrumentation will be minimal. Brooks Instrument MFCs (mass flow controllers) measure and control the mass flow of fluid going through a line or pipe using a thermal sensor that measures the differential temperature created by the flowing fluid, rather than measuring any changes in physical mass. Still, let’s explore the rich history of the kilogram, why it’s changing, and what it will mean moving forward.

History & Limitations of the Kilogram

Up until the recent change, the master standard of one kilogram was a piece of platinum-iridium metal stored in a vault in Paris. As is true with all physical matter, the piece of metal formerly known as a kilogram was susceptible to slight deterioration in mass over time. Since the metric system is based on precise measurement of base units like the kilogram, it’s important that the standard for the base unit be constant. This could not be said about that piece of platinum-iridium metal stored in a vault in Paris, or any physical mass for that matter.

Planck's Constant

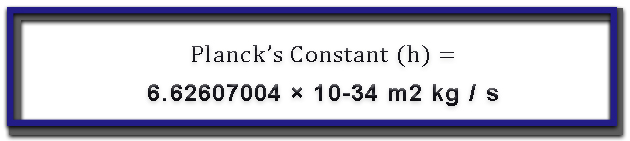

To overcome the uncertainties associated with measuring a physical mass, the scientific community agreed to define the kilogram using a more universally constant method of measurement. The speed of light, for example, is a universally constant number – it is not susceptible to external factors or conditions, unlike a mass of metal. Another example is the Planck constant, “h”, named after a famous German physicist by the name of Max Planck. Originally related to the quantization of light and matter, the official kilogram is now based on the Planck constant.

Looking at the units for Planck’s constant, scientists can readily define both length (m) and time (s). Using complex mathematics, scientists can then derive the mass unit (Kg) from knowing the precise value of “h”. This is how the new kilogram was born.

Using the more precise Planck’s constant method for defining the standard kilogram eliminates measurement errors that stem from physical deterioration of the piece of metal over time. Scientists now claim that with by using Planck’s constant, the margin of error is a few billionth of Kg (1x10-9 Kg).

What does this mean for Mass Flow Control & Instrumentation?

So how does the change in the standard kilogram affect your process instrumentation? In short, it won’t. Brooks Instrument calibrates all its gas mass flow devices using precision volumetric calibration equipment that is directly traceable to these international standards. A volumetric calibration technique is used because changes in gas volume are much easier and faster to measure than changes in mass. The accuracy of the mass flow device depends in part on the calibration system measurement uncertainties - in time, temperature, volume and pressure measurements. In addition to traceability to international standards, Brooks Instrument maintains calibration systems certified to ISO 17025. This ISO 17025 accreditation requires a full understanding of the measurement system uncertainties and ensures via a third-party audit that processes and procedures are in place to maintain these systems.

While the international standard for mass has changed, one thing that has not changed is the continued quality and reliability of Brooks Instrument devices. Interested in learning more about how metrology, reference standards and calibration affect long-term MFC performance? Click here to read.