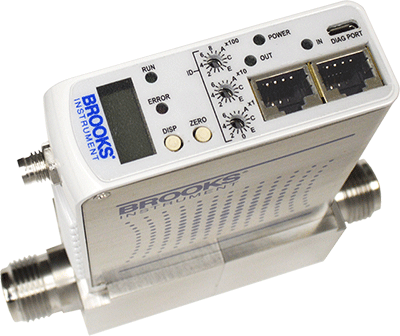

In this two-part blog series, we first explored the architecture and performance characteristics of the EtherCAT® protocol. Now, we will examine how Brooks leverages the real-time data acquisition capabilities of EtherCAT® in the GF100 Series MFCs.

Leveraging Embedded Diagnostics

Leveraging the real-time data acquisition capabilities of EtherCAT, the GF100 Series MFCs detect exception conditions and reports these via EtherCAT. These exceptions can also be seen on the integrated device display and can be masked separately from the network if the user chooses to.

The severity of the exception will affect how it may be displayed and what action the device may take when the exception occurs. These alarms can be crucial in the early detection of potential issues in a process.

• FAIL Status: Component failures or configuration issues that may result in the device being grossly inaccurate or otherwise unable to control flow, will place the device into a safe state, but are unlikely to occur.

• ERR Status: Errors are typically process related and report conditions that may affect flow accuracy. Some errors allow for user configurable limits, enabling customized process monitoring for conditions such as process flow or pressure being out of range, or customized process deviation error bands.

• WARN Status: Alerts are informational notifications to the user about the device such as warm up, mounting orientation and input voltage.

The default PDO mapping includes a summary attribute that displays the active exception status of the device using EtherCAT’s high-speed data exchange. This ensures the user is receiving concise and relevant exception information by only using one object in the PDO. The display of any exception condition on the device LCD screen can also be enabled or disabled individually for additional customization.

Through hundreds of thousands of installations, the GF100 Series has proven its value as the fastest and most accurate MFC series in the industry. With the addition of real-time information that EtherCAT supports, engineers have powerful new reasons to “design-in” GF100 Series MFCs, and thereby enhance the performance, control and long-term return on investment of their advanced automation systems, particularly for semiconductor applications.

See the performance yourself: Request a FREE demo GF100 Series MFC with EtherCAT now!