Winemaking is centuries-old artform that requires a delicate balance between nature and technology to make a flavourful and consistent product. This blend of biology and chemistry poses certain threats, primarily bacterial contamination, and chemical oxidation. Either could adversely affect the wine’s quality, flavour, colour, and aroma, leading to variation and possible spoilage. The solution? Sparging, or the infusion of gases such as nitrogen, argon or carbon dioxide via very fine bubbles which absorb and remove dissolved oxygen and volatile contaminants from fermenting wine.

Application Requirements

The wine producer has partnered with Brooks Instrument over many years to continually improve their sparging process.

Every few months, crush season arrives for the wine producer, where tons of grapes are crushed and pressed around the clock. The resulting pre-mature wine, or “must,” then flows into many gigantic tanks for fermentation. Sparging starts to take place. An operation of this size requires a speedy and efficient process, minimal downtime, and above all: consistency. For years, sparging has been an automated process where

Brooks Instrument mass flow controllers deliver the sparged gas at precise amounts for batch consistency. However, a new challenge arose when they discovered liquid had entered the mass flow controller through its outlet. After some troubleshooting, Brooks Instrument flow experts found a failed downstream check valve which allowed the wine to flow out of its tank, up through the gas line, and into the flow control instrument, thus fowling the device – this “event” is known as

back streaming. The only solution was to replace both the mass flow controller and the check valve, which meant downtime and avoidable replacement/repair costs.

Instrument Highlights

- A digital mass flow controller with built-in alarms and advanced diagnostics alerts the operator to take action before damage occurs

- Accurate and repeatable gas flow for process consistency to avoid process variation and spoilage

- EtherNet/IP™ digital communication interface enables high speed communication to minimise back streaming

- NEMA4x/IP66 rated hardened enclosure to handle the washdown requirements the mass flow controller would be exposed to (More on this below)

Process Solution

To solve the issue of back streaming while meeting the application’s requirements for accuracy, repeatability, the Brooks Instrument SLAMf Series mass flow controllers with EtherNet/IP™ digital communication protocol was recommended. The digital mass flow controller’s advanced diagnostics and alarm capabilities were quickly configured into the customer’s PLC in the event back streaming does happen.

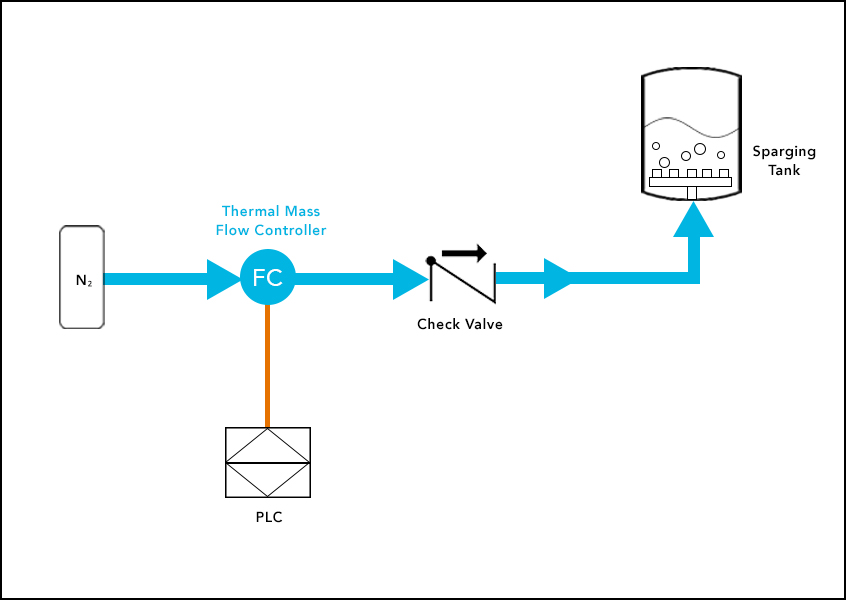

Let’s look at the process with the SLAMf Series mass flow controllers with EtherNet/IP™: gas flows from the storage tank, through the Brooks Instrument mass flow controller, then into the air tube which is fed into the wine tank. The SLAMf Series mass flow controller with EtherNet/IP communication protocols constantly measures the sparged gases and controls the rate that they are exposed to the liquid. The SLAMf Series offers high accuracy over a wide range of gas flows and pressures as well as a consistent delivery of a precise quantity of bubbles, which is critical during the oxidation process, determining the aroma and subtle variations of the wine taste.

The back streaming challenge was resolved by detecting its occurrence early before the wine reached the mass flow controller. This is achieved by configuring the mass flow controller in the PLC to send a signal via EtherNet/IP™ digital communication protocol which analyzes the total flow. Once backflow is detected, an alarm is immediately triggered, alerting the system to close the downstream shut off valve. This stops the reverse flow of wine and saves the instrument from contamination, avoiding costly delays in downtime and instrument repair.

The Brooks Instrument SLAMf Series mass flow controller with a NEMA4X/IP66 rated hardened enclosure was also recommended to handle the outdoor elements of dust, moisture, and temperature variations and washdown requirements.

Component datasource missing. Select a datasource for this component.