Plasma etch and photoresist strip processes are crucial points in front-end-of-line (FEOL) semiconductor fabrication steps. These processes can leave behind unwanted polymer residues that are a by-product of aggressive chemistries used in these etch and strip steps.

For a couple of decades, one of the technologies used to facilitate the removal of these residues has been the introduction of ultra-pure deionized water vapor in the plasma chemistry. As with virtually all aspects of semiconductor fabrication, there is extraordinary attention paid to controlling the variables in every process step, to help ensure the highest levels of uniformity and microchip yields.

This includes controlling, to the greatest extent possible, the volume, flow rate and purity of water vapor used in residue removal processes. Brooks Instrument has recently introduced a

new Vapor Delivery Module, the VDM300, that utilizes a unique vapor delivery technology approach that is up to 30 times more accurate and repeatable than competing vapor delivery systems.

Solution: Constant Delivery Pressure (DP)

Based on proven thermal mass flow measurement techniques and the field-proven, reliable VDM100, the VDM300 reduces process variability through accurate and repeatable water vapor flow delivery, as well as offering a wider control range.

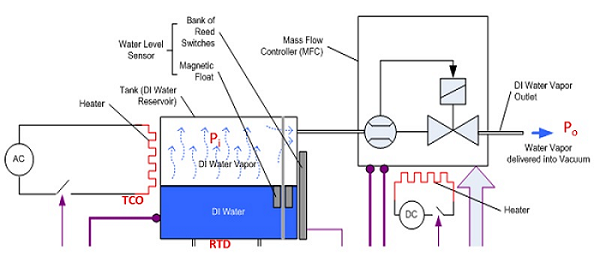

The VDM300 produces vapor in a passivated titanium vessel in a non-super-heated vapor stage. The reservoir contains deionized (DI) water that is heated to a tightly controlled range: 90.7 ±3°C.

Since the temperature is kept extremely stable, the upper part of the VDM300 chamber contains a constant supply of the non-super-heated vapor. The tank’s vapor pressure is thus, in turn, also precisely controlled: from 487 - 611 torr. The vapor is delivered into the vacuum chamber through a Brooks mass flow controller (MFC) integrated into the VDM300 and using the same ultra-precise thermal mass flow control signal processing and calibration techniques used by our industry-leading GF100 Series MFCs.

This design makes it possible for the VDM300 to achieve stable flow by maintaining a constant DP across the MFC:

- The Inlet MFC water vapor pressure is a function of the tank temperature

- The Outlet MFC pressure into the vacuum chamber is determined by the chamber/line pressure

This technology approach enables the VDM300 to provide industry-best vapor delivery accuracy and repeatability: ±1% S.P. flow accuracy, rated as being more accurate than competing vapor delivery systems.

This technique yields chemically pure water vapor, free of decomposition by-products or other contaminants. In essence, the VDM300 continuously “distills” the DI water vapor while maintaining a constant vapor pressure into the MFC. In addition, the passivated titanium tank and UHP 316L SS “wetted path” materials of construction help minimize the chance of nonvolatile contaminants being introduced into the process chamber.

The result: Semiconductor photoresist strip and polymer residue removal processes that require the use of DI water vapor have the level of accuracy, repeatability and cleanliness that today’s most demanding semiconductor fabrication processes require.

VDM300: Newest generation of Vapor Delivery Modules

With the combination of the highest accuracy, repeatability and wider control range, the VDM300 offers users the widest process recipe flexibility to meet their unique needs. It also features EtherCAT® communication, which provides the kind of enhanced, high-speed digital communications that support next generation process equipment platforms.

For a quick overview of the VDM300’s key features, download our VDM300 At-a-Glance Product Brief.

For more technical information and application support, visit the VDM300 Product Page.

Component datasource missing. Select a datasource for this component.